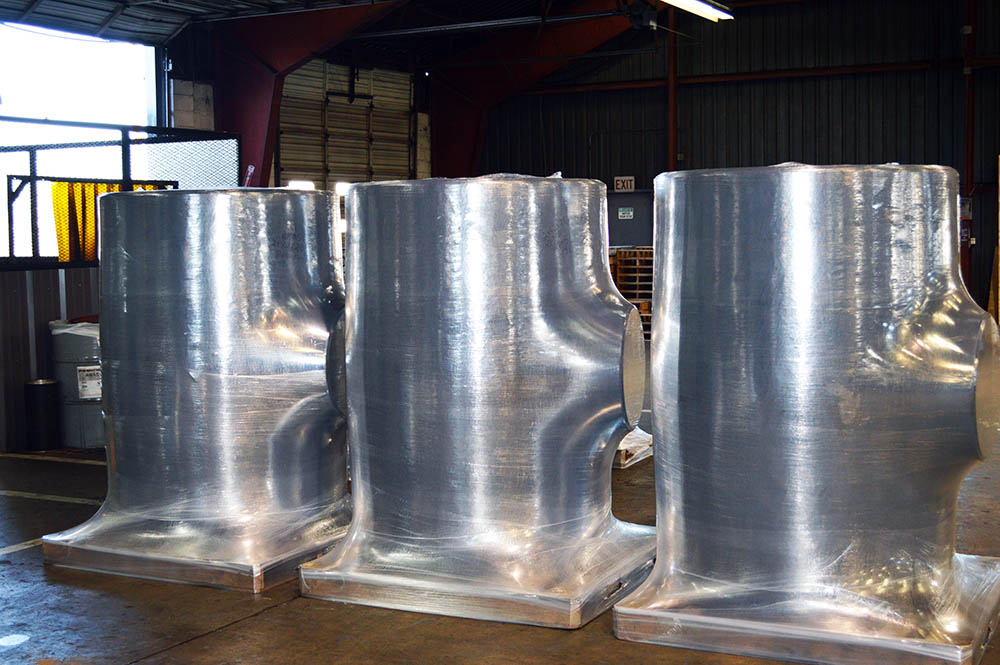

Butt-Weld Fittings and Their Applications

Whether the pipe is buried in the earth or exposed to the elements, butt-weld pipeline fittings are a key component of oil and gas transportation architectures. A steel butt-weld fitting plays a crucial role in keeping the pipeline from failing from the massive pressure flows. Butt-weld fittings allow directional changes in the liquids or gasses … Read more