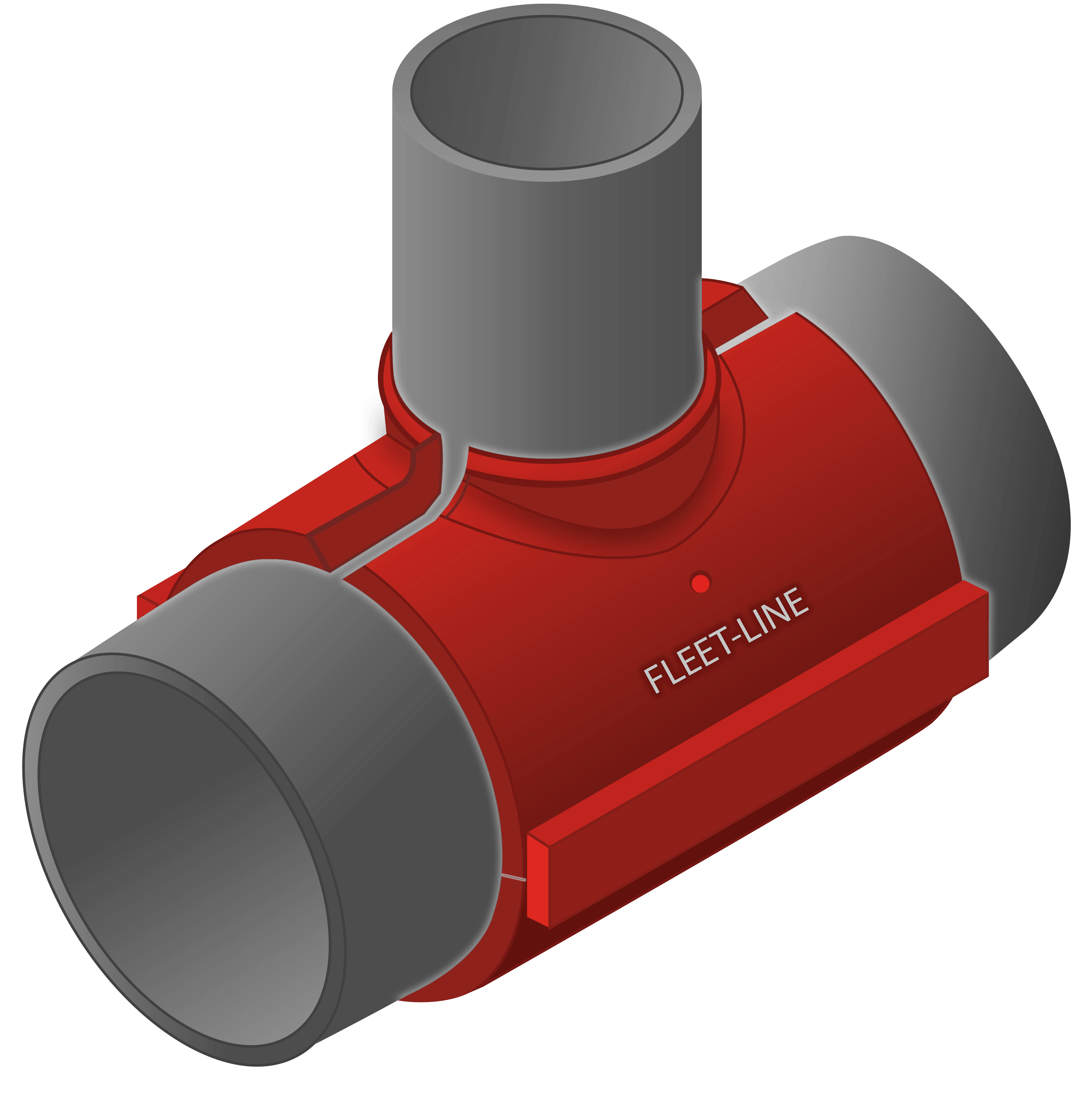

Full Encirclement Saddle

Full-Encirclement Reinforcing Saddles are used to provide reinforcement for branch outlets when the code dictates further strength may be required. Although full-encirclement reinforcing saddles are designed to fully encircle the run pipe, saddles are not designed to be pressure retaining. All full encirclement saddles come with a vent hole to expel welding gases. Every full-encirclement reinforcing saddle is shipped with proper mill test documentation. We offer five types of encirclement weld saddles to suit your customer needs. May be offered with side bars or beveled sides. If beveled sides are specified, a backing groove and backing strips are provided.

All Steel Forgings saddles are made from top-quality steel that meets all standard legal specifications for measures like strength and corrosion resistance.

Description

- Available for full size or reduced branch outlets down to 2″.

- Many sizes and styles available for fast shipping.

- Satisfies the requirements of ASME B31.1, B31.3, B31.4, B31.8 and other applicable design codes.

- Various Full-Encirclement Reinforcing Saddle styles available: Part 1 to Part 5.

Steel Forgings can supply Full-Encirclement Reinforcing Saddles in any of the five configurations commonly used in the industry:

Part No. 1

Single piece construction, split into two equal halves through the branch.

Part No. 2

Single piece construction, split longitudinally through the run perpendicular to the branch.

Part No. 3

Two piece construction, composed of a run cylinder welded to a plate saddle, split into two equal halves through the branch.

Part No. 4

Two piece construction, composed of a run cylinder welded to a plate saddle, split longitudinally through the run perpendicular to the branch.

Part No. 5

Single piece construction, cut into three sections by splitting through the branch and through the run perpendicular to the branch.

To quote a full encirclement saddle we need the following:

- Run pipe size

- Outlet pipe size

- Thickness and grade of the run pipe

- Which part number

- Specification

| Run Pipe Size | 2", 3", 4", 6", 8", 10", 12", 14", 16", 18", 20", 22", 24", 26", 30", 34", 36", 40", 42", Other (Please describe in Notes) |

|---|---|

| Run Pipe Wall Thickness | 0.375", 0.500", 0.625", 0.688", 0.750", 1.000", 1.125", 1.250", Other (Please describe in Notes) |

| Branch Pipe Size | 2", 3", 4", 6", 8", 10", 12", 14", 16", 18", 20", 22", 24", 26", 28", 30", Other (Please describe in Notes) |

| Branch Pipe Wall Thickness | 0.375", 0.500", 0.625", 0.688", 0.750", 1.000", 1.125", 1.250", Other (Please describe in Notes) |

| Material | WPB, Y42, Y52, Y60, Y65, Y70, WPL6, Other (Please describe in Notes) |