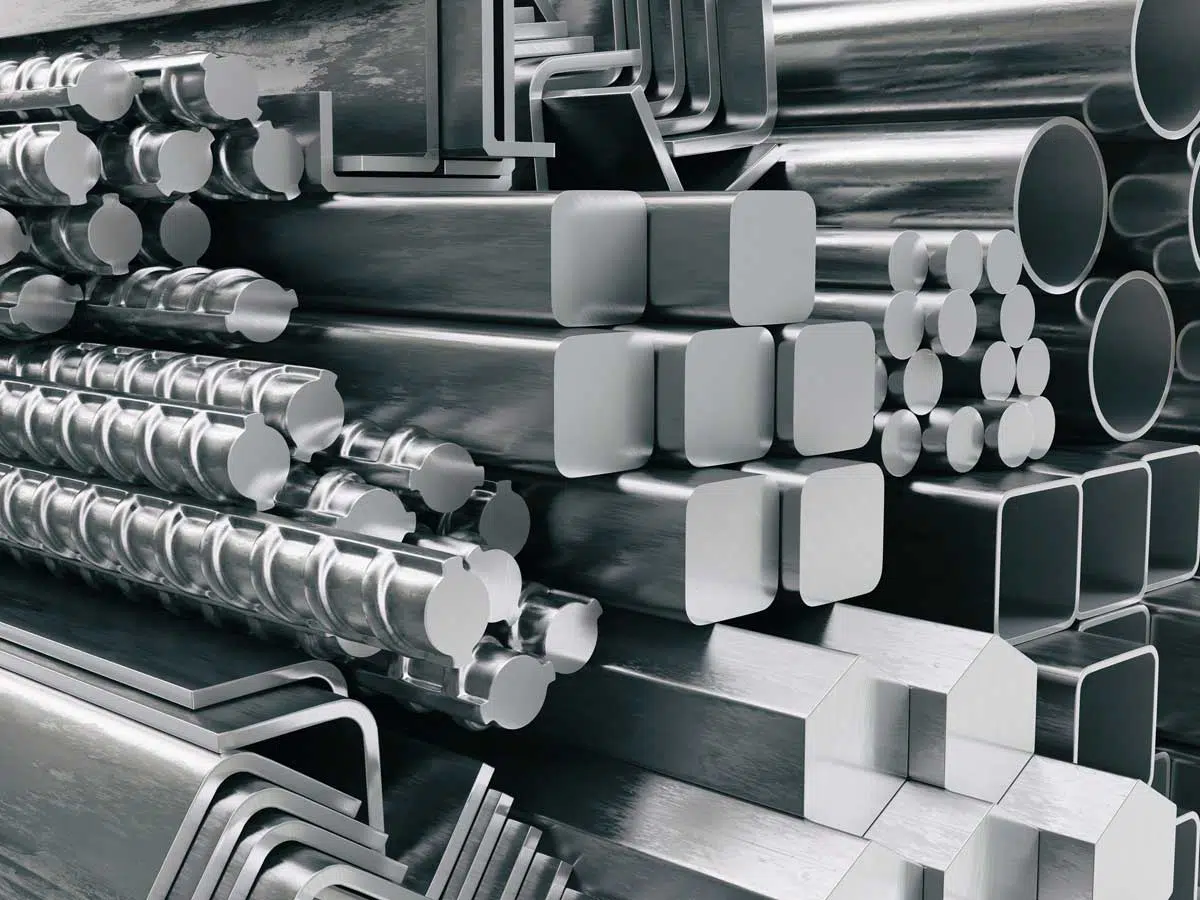

There are few materials today as useful and durable as steel. Throughout the oil and gas industry, there are many types of steel that are incredibly important to the process. Let’s take a look at the types of steel in oil and gas industry applications.

High Yield Steel

WPHY42 – WPHY70 fittings are made from this.

Carbon Steel

WPB Fittings are made from this

Carbon steel is a strong, common steel that contains about 2 percent carbon. For most applications, carbon steel will be used. The challenge with carbon steel is that it is more susceptible to corrosion than stainless steel is, so the parts are more likely to need to be replaced or repaired. But carbon steel is cheap and durable, so often there aren’t benefits to using the more expensive stainless steel in its stead. It can be further augmented with coatings or chemicals, to help it resist corrosion on a similar level to stainless steel.

Nickel Alloy Steel

Nickel alloys are frequently used throughout the oil and gas industry. Nickel-plated steel might also be used. Nickel-alloy stainless steels tend to be easier to form and can be used for high-temperature applications. They are non-magnetic and, most importantly, they have resistance to corrosion. Much like regular stainless steel, nickel-alloy steel will be used in situations in which it’s important to fight off corrosion, or in which ease of maintenance and durability is ideal. It is still more expensive than traditional carbon steel, but easier to repair and maintain.

Stainless Steel

Most people are familiar with stainless steel. But it’s not just gorgeous in kitchens, it’s also important in oil and gas infrastructure. Stainless steel has 10.5 percent or more chromium. This creates a passive layer that can protect the steel from corrosion, one of the major dangers within oil and gas. Parts that are made with stainless steel require far less maintenance, are less likely to break, and are consequently far safer to use. Stainless steel still has many of the other advantages of steel, as it is durable and long-lasting. Other materials may be added to stainless steel, such as nickel, that will further protect it from corrosion.

Those are some of the different types of steel used in oil and gas. There are many types of steel in oil and gas industry infrastructure, varying on what their needs and requirements are. For more information about how the oil and gas industry is served by the best steel, contact the experts at Steel Forgings.