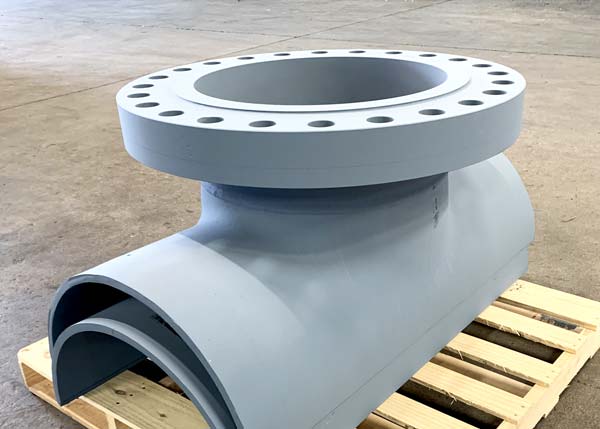

Hot Tap Tee

A hot tap, involves creating new connection to an existing pipe without emptying it or interrupting the flow. Pipeline hot tapping is typically used as a tie-in point for new piping, but is also often performed as a means to deploy instrumentation without shutdown. Hot tapping machines are often deployed in an essential step in preparation for line stopping.

Fleet-Line hot-tap tees are designed for use with class 150#, 300#, and 600# RFWN flanges for ASME B31.8 application, as well as other B31.8 and industry codes and standards. We can quote hot-tap tees with or without a flange.

Given the often sensitive nature of hot tapping, it is critical for hot tap tees to be made to the highest, most rigorous standards, which Steel Forgings excels in. All Steel Forgings hot taps are made from top-quality steel that meets all standard legal specifications for measures like strength and corrosion resistance.

Description

To quote a hot-tap tee we need the following information:

- Run Pipe Size

- Outlet Pipe Size

- Thickness and Grade of Material

- Specification

- Flange Class

| Run Pipe Size | 2", 3", 4", 6", 8", 10", 12", 14", 16", 18", 20", 22", 24", 26", 30", Other (Please describe in Notes) |

|---|---|

| Run Pipe Wall Thickness | 0.375", 0.500", 0.625", 0.688", 0.750", 1.000", Other (Please describe in Notes) |

| Branch Pipe Size | 2", 3", 4", 6", 8", 10", 12", 14", 16", 18", 20", 22", 24", 26", 30", Other (Please describe in Notes) |

| Branch Pipe Wall Thickness | 0.375", 0.500", 0.625", 0.688", 0.750", 1.000", Other (Please describe in Notes) |

| Material | WPB, Y42, Y52, Y60, Y65, Y70, WPL6, Other (Please describe in Notes) |