- ISO Certified: 9001:2015

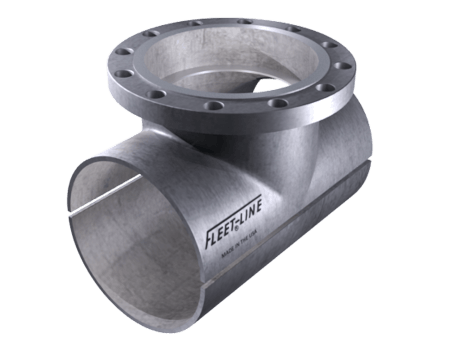

Steel Forgings Inc. has been a leading manufacturer of butt weld fittings for the oil and gas industry for over 70 years. Our Fleet-Line products are well respected and known throughout the industry as top quality. Our Mission is to lead our industry in quality and service for quick turn-around fittings for the pipeline industry. Steel Forgings strives to be the first and last call for our customers.

Browse Our Products

Quality Steel Manufacturing

Steel Forgings “Quality Management System” is an ISO 9001:2015 registered system that has been maintained since 1999. Within the confines of this quality system are many processes that ensure a quality product is delivered to the customer.

Welding

All pressure containing or critical welds are performed by welders qualified per the requirements of ASME Sec. IX. Longitudinal weld seams are double submerged arc welded.

Non-destructive testing

Steel Forgings employs a third-party inspection firm to perform all NDE requirements onsite, whether they are customer- or industry-driven. All NDE procedures have been approved by Steel Forgings and all NDE technicians have been tested in accordance with ASNT-TC-1A requirements.

Heat Treatment

All furnaces have a uniformity survey conducted yearly, and all recorders are calibrated quarterly to ensure the fittings are heat treated at the correct temperature.

Final Inspection

Each fitting has a complete dimensional inspection prior to preparation for shipping. All of these critical operations are considered a hold point in the fabrication process and are required to be signed off prior to being sent to the next operation.

No one can manufacture saddles quite like Steel Forgings. One of the company’s founders, Arthur Fleet Davis, wrote the patent for pipe saddles.

We offer the quickest turn around in a large variety of sizes and thicknesses, and always the highest quality.